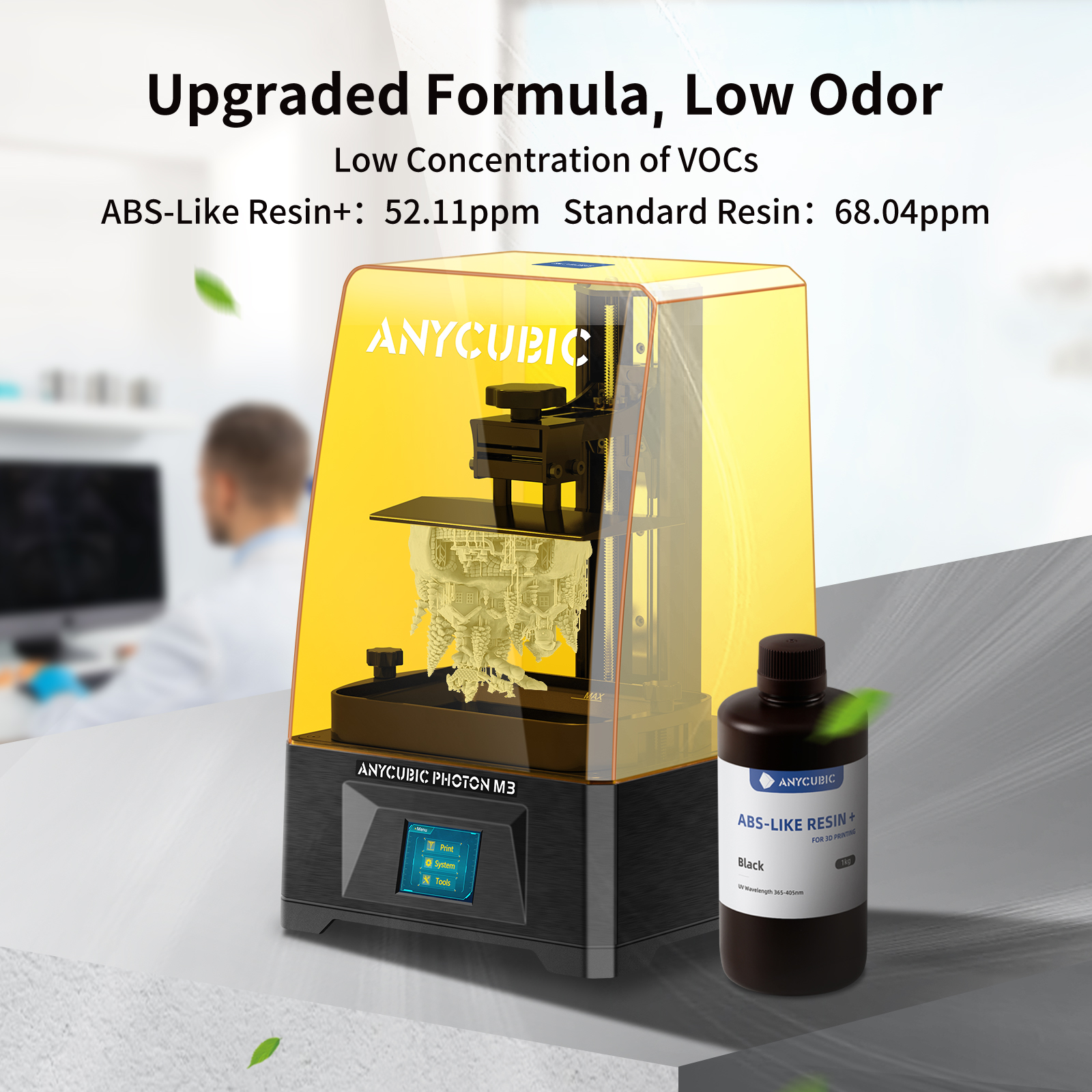

Anycubic ABS-Like Resin+

Anycubic ABS-Like Resin+

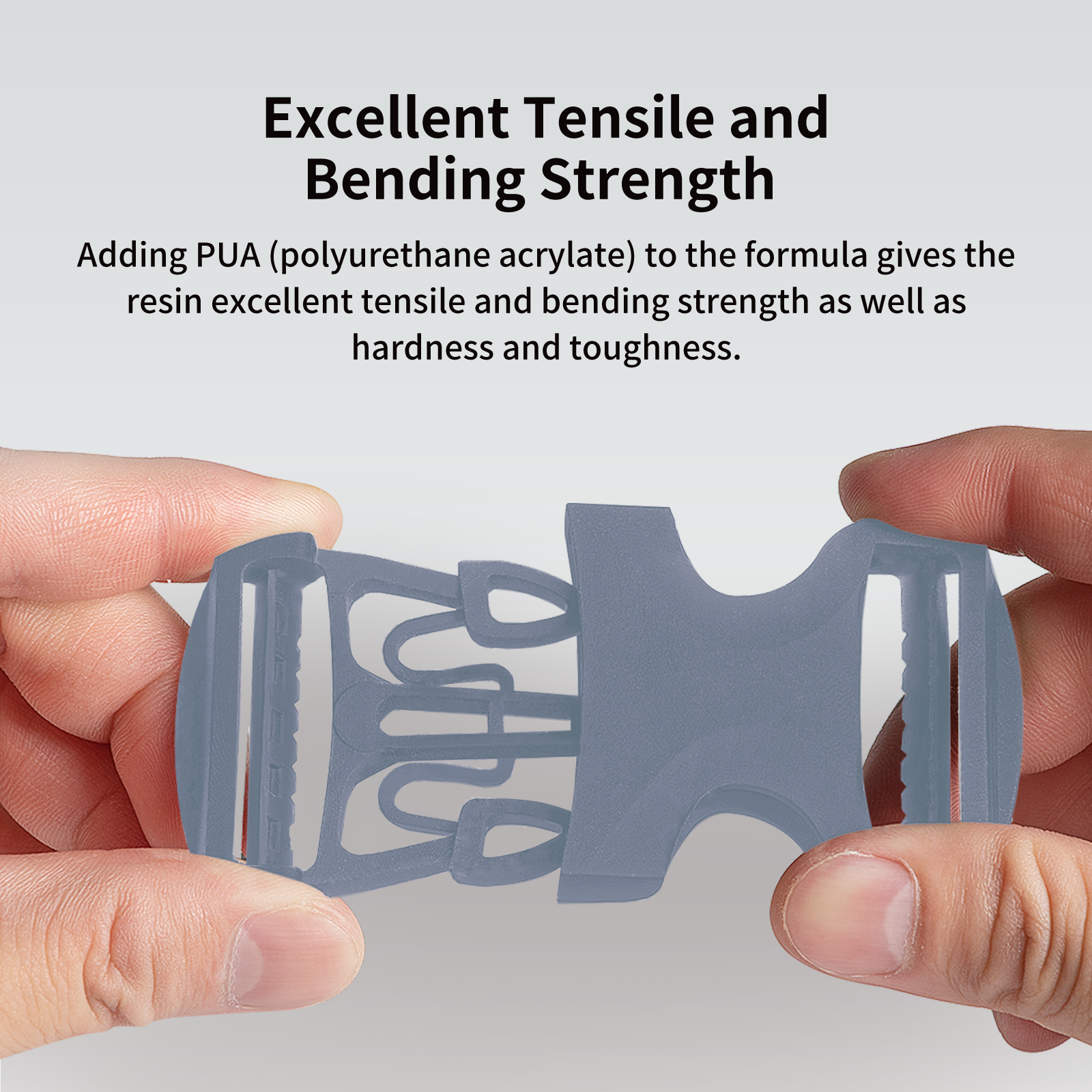

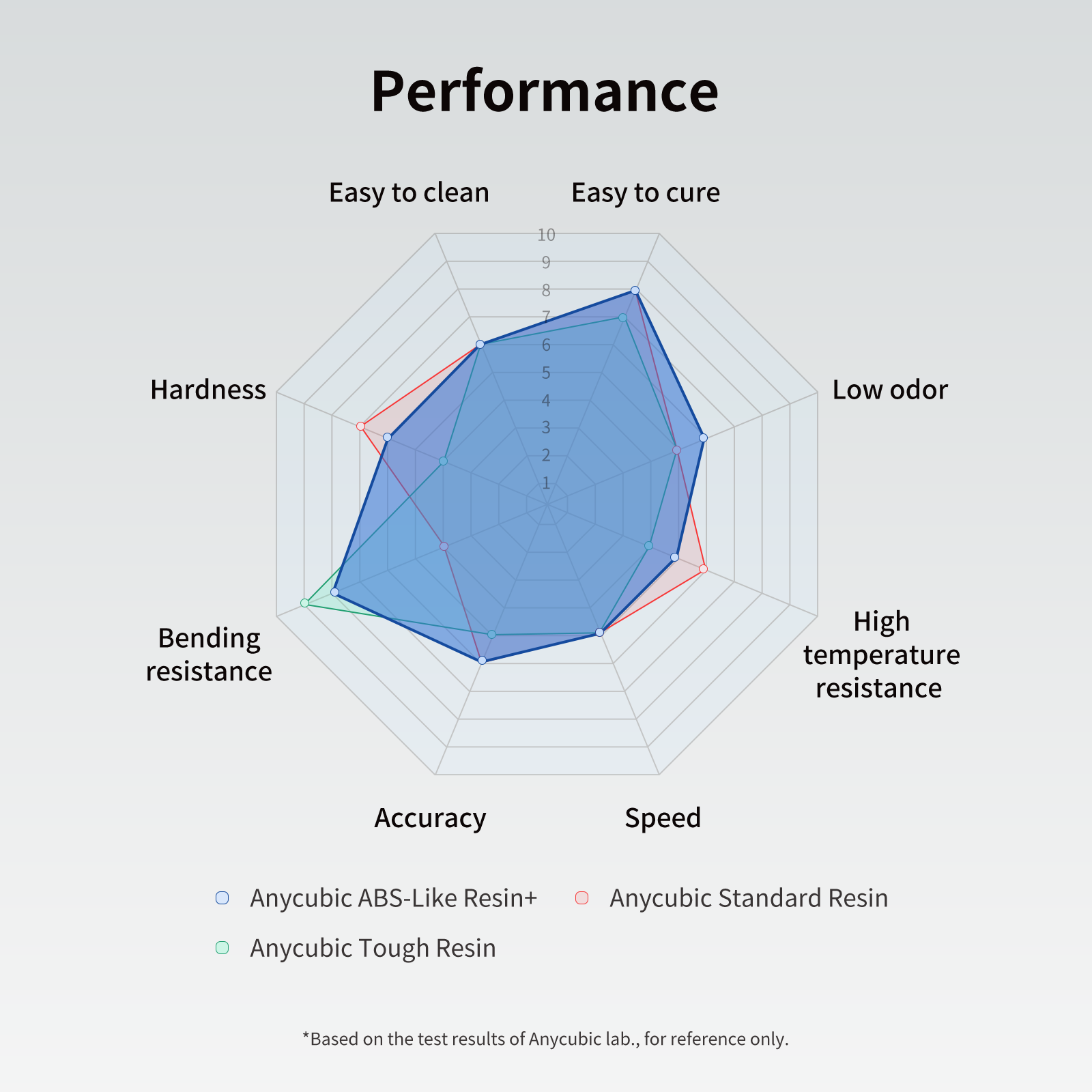

【𝐄𝐱𝐜𝐞𝐥𝐥𝐞𝐧𝐭 𝐓𝐞𝐧𝐬𝐢𝐥𝐞 𝐚𝐧𝐝 𝐁𝐞𝐧𝐝𝐢𝐧𝐠 𝐒𝐭𝐫𝐞𝐧𝐠𝐭𝐡】 Adding PUA (polyurethane acrylate) to the formula gives the resin excellent tensile and bending strength as well as hardness and toughness.It has past extensive testing and can perform under a normal tensile force and compressive stress. It can be stretched with good crack resistance capability so as to ensure no breakage on the model

【𝐅𝐚𝐬𝐭 𝐏𝐫𝐢𝐧𝐭𝐢𝐧𝐠 𝐚𝐧𝐝 𝐇𝐢𝐠𝐡 𝐈𝐦𝐩𝐚𝐜𝐭 𝐒𝐭𝐫𝐞𝐧𝐠𝐭𝐡】Benefiting the upgraded formulation, anycubic ABS-like resin+ has good fluidity, which can effectively increase printing speed, success rate and are easy to clean. And this 3D printing resin has an excellent combination of stiffness and toughness. It is not fragile and strong enough to withstand accidental falls from time to time

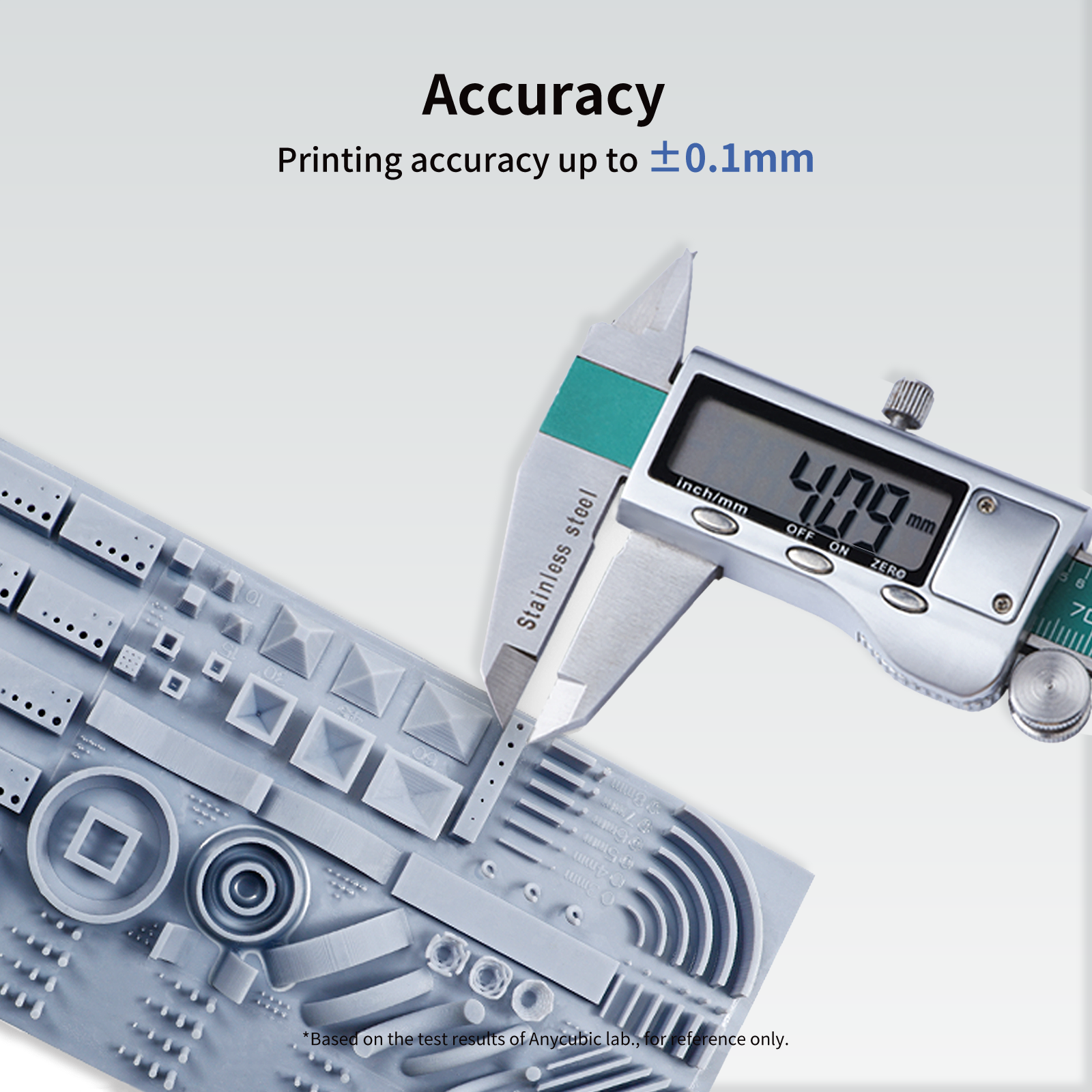

【𝐁𝐞𝐭𝐭𝐞𝐫 𝐅𝐥𝐮𝐢𝐝𝐢𝐭𝐲 𝐈𝐦𝐩𝐫𝐨𝐯𝐞𝐬 𝐭𝐡𝐞 𝐇𝐢𝐠𝐡 𝐏𝐫𝐞𝐜𝐢𝐬𝐢𝐨𝐧】Improved fluidity significantly reduces curing time, and ensures a printing accuracy of ±0.1mm. It can provide high accuracy, smooth surface, clear print details and low shrinkage rate advantages for model printing. Take a full shake before use in order to have a fully mix the functional components and fully mix the color paste in the resin. Otherwise, uneven coloring of the print may occur.

【𝟏𝟖-𝐦𝐨𝐧𝐭𝐡 𝐄𝐱𝐩𝐢𝐫𝐚𝐭𝐢𝐨𝐧 𝐃𝐚𝐭𝐞】Most resin for 3D printing have a expiration date of only one year. With upgrades to the formula and packaging, Anycubic ABS-Like Resin + extends its expiration date to 18 months. In order to reduce the probability of 𝐲𝐞𝐥𝐥𝐨𝐰𝐢𝐧𝐠 of the transparent model, it is suggested that: 1. The curing time after the model is controlled within 2-3minutes; 2. Do not dry the molded model in the sun

【𝐖𝐢𝐝𝐞𝐥𝐲 𝐂𝐨𝐦𝐩𝐚𝐭𝐢𝐛𝐥𝐞】As a leading manufacturer and pioneer for global desktop 3D printers, Anycubic put the compatibility to LCD and DLP at the center of its attention while developing the ABS-Like Resin +, making it compatible for most printers of both types

Anycubic ABS-Like Resin+ Tough and Easy to Post-process Strong Formula | High Precision | Long Lasting